BenePackaging has 15 years of experience in flexible packaging production, strictly abides by the ISO9001 management system, and provides customers with overall packaging solutions. We have departments such as blow molding, printing, inspection machine, compounding, slitting, pouches making, inspection, logistics and warehousing. It has a full process production process, 10 bag making production lines, and multiple 10 color full-automatic high-speed printers to ensure that product quality, technology development, delivery schedule and other aspects are carried out in an orderly manner.

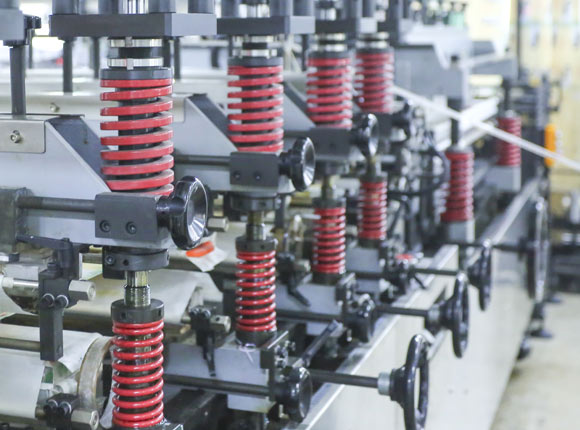

Our factory is located in Linyi High tech Zone. At present, the company’s equipment includes 70+sets of film blowing machines, 10 color high-speed gravure printing machines, compound machines, high-speed slitting machines, high-speed palm folding machines, high-speed label cutting machines, high-speed double independent zipper bag making machines, etc. More than 100 technical and management personnel with more than 10 years of work experience are employed.

The customization of food packaging bags requires a complicated communication process before production and processing, including the material combination, bag type, size, thickness, quantity, printing pattern, etc. of the packaging bags, including whether to add easy tear holes, zippers, hanging holes, air holes and other details, which need to be determined before plate making. Then the packaging manufacturer will make plates and order materials according to specific requirements, and begin to prepare for production. Our sales representatives, packaging experts and logistics teams will actively help you in all stages of order execution, so that you can experience the professionalism and ease of communication in the process of customizing packaging bags.

I worked with Kim and he was very helpful. He got responses back to me extremely quickly and was able to get my project completed sooner than I expected. Really impressive quality, I will definitely be ordering in the future.

Their designer and packaging team know what customer is looking for. Great service and awesome quality. Would definitely work with them again.

BenePackaging provided an excellent service for us in a professional and personable efficient manner. The price was cheaper than other supplies and the pouches were of good quality. Best print quality we’ve ever used.